Solution Services

Board Design

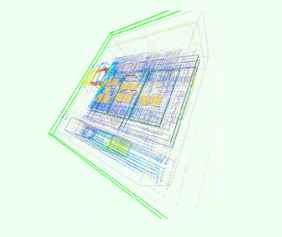

Board design

Board design

We provide turnkey PCB solutions from circuit design to PCB manufacturing.

And PCB design optimization for high-speed transmission with SI/PI board simulation. Cooling solutions for

product miniaturization with thermal, fluid and stress-strain analysis.

Best Solutions for

Best Solutions for

Customer Problems

We provide concurrent PCB design solution that integrate electrical and thermal fluid/stress simulations for customer's product developments.

01

Design PCBs with low warpages

We perform warpage analysis, using Cu ratio model based on the real PCB designs. We propose optimized PCB designs low warpages whether BGAs are used.

02

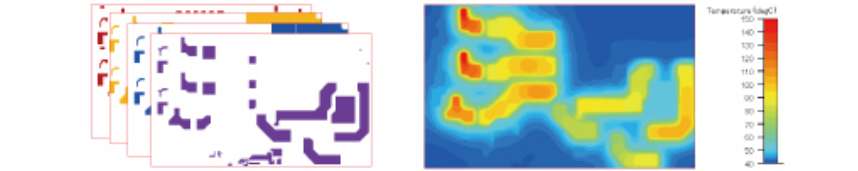

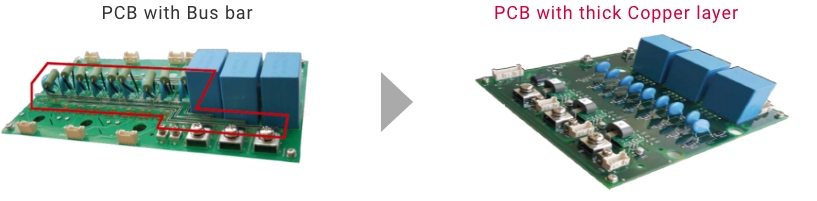

Design PCBs with joule heat analysis for high current applications

We propose optimal PCB designs with thermal analysis that integrate joule heat and device operating heat analysis.

【1】Perform joule heat analysis with

precise trace pattern modeling

based on

the

real designs.

【2】 Improve trace flexibility with Embedded Bus Bar.

【3】Place control logic and power devices on the same surface layer.

03

Realize stable operation for high performance PCBs

Our optimized PCB design solutions for high performance applications reduce prototype cycles, lead-time, and cost.

【1】Suitable PCB specifications

Optimum materials, Layer structure and design rules

【2】Signal Integrity(SI)Analysis

Waveform quality and timing of high-speed DDRx interface.

【3】 Power Integrity(PI)Analysis

Check DC Drop and Input Impedance of Power Line for Digital Board.

【4】VG plane resonance analysis

Check VG plane resonance for Digital Board.

Application Fields

Application Fields

We provide comprehensive design solutions for performance, miniaturization, and cooling in a

wide range of products, devices and modules.

With our extensive experiences in a wide variety of areas, we offer value-added design solutions for our

customers.

01

High performance PCBs for Super Computers, ICT Infrastructure and Medical

systems

| Board Size | 440 x 350mm |

|---|---|

| Structure | 24 Layers |

| Device counts | 8,400 |

| Device Pin counts | 39,000 pin |

| Wire counts | 30,000 wires |

More details for "High Density Interconnect PCBs"

Read More

02

High density PCBs for Automotive, mobile and IoT

| Board Size | 70 x 550mm |

|---|---|

| Structure | 12 Layers (5-2-5) |

| Device counts | 13,000 |

| Device Pin counts | 6,200 pin |

| Wire counts | 1,500 wires |

More details for

"HDI (Buildup) PCBs"

03

Thick Cu PCBs for Industrial and Power electronics

(Thick Cu for high current use)

| Board Size | 180 x 110mm |

|---|---|

| Structure | 4 Layers |

| Device counts | 60 |

| Device Pin counts | 250 pin |

| Wire counts | 160 wires |

More details for

"Thick Copper PCBs"

04

Semiconductor packaging substrates

| Board Size | 72 x 65mm |

|---|---|

| Structure | 20 Layer(6-8-6) |

| IO counts of DIE | 3,500 pin |

| BGA Pin counts | 30,000 pin |

More details for

"Package Substrate"

05

High layer count PCBs for Semiconductor tests

| Board Size | 100 x 100mm |

|---|---|

| Structure | 51 Layers(14-23-14) |

| Device counts | 6 DUT |

| Device Pin counts | 55,800 pin |

| Wire counts | 3,500 wires |

| Board Size | φ520mm |

|---|---|

| Structure | 76 Layers |

| Device counts | 28,700 |

| Device Pin counts | 107,500 pin |

| Wire counts | 35,600 wires |

More details for

"Probe Cards"

Design Tools and Environment

Design Tools and Environment

We provide total PCB design solutions that include a wide range of simulations. We interface design data to a large variety of tools for electrical, thermal, and stress-strain simulations to add values to our customer's products.

PCB Design Center

Nagano headquarters

Kawasaki office

FICT VIETNAM COMPANY LIMITED

Electrical Simulation

Electrical Simulation

We design the high-speed digital board using electrical simulation to satisfy Signal and Power Integrity.

Signal Integrity

SI simulation by using 3D electromagnetic field simulator

We design high-speed digital board using electromagnetic field simulation.

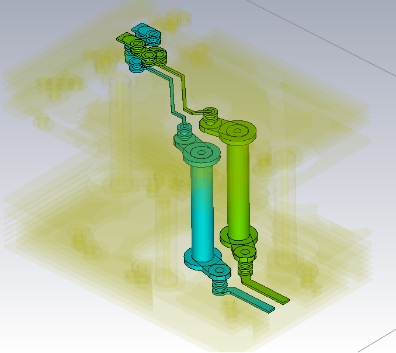

3D model of differential

signal for Module Board

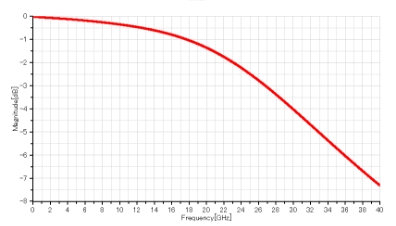

Insertion loss "SDD21"

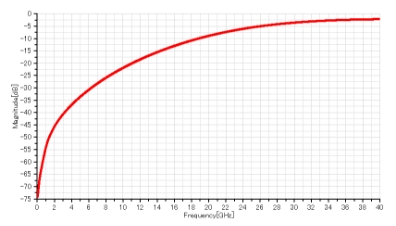

Return loss "SDD11"d

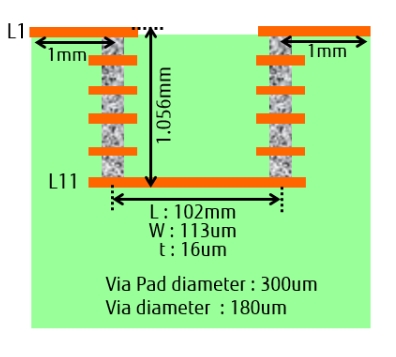

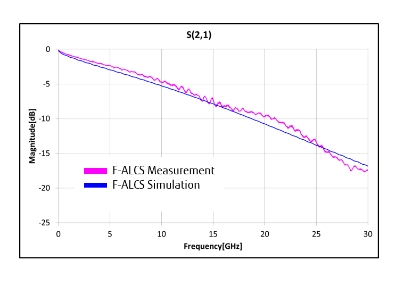

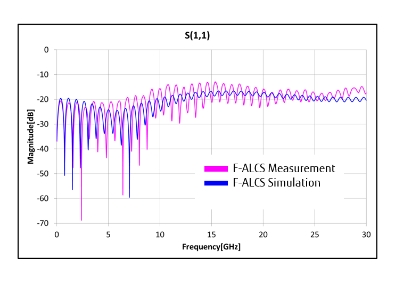

Example of transmission characteristics analysis of

F-ALCS structural substrate

The transmission characteristics analysis results and measurement results for the F-ALCS wiring structure are shown below.

F-ALCS PCB Model

Insertion loss S21

Return Loss S11

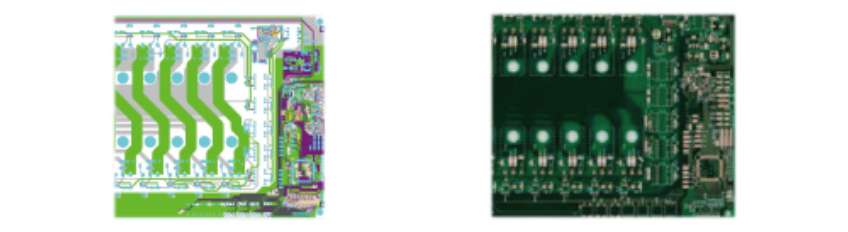

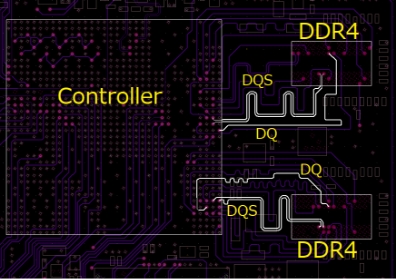

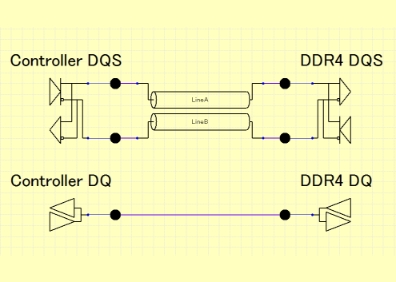

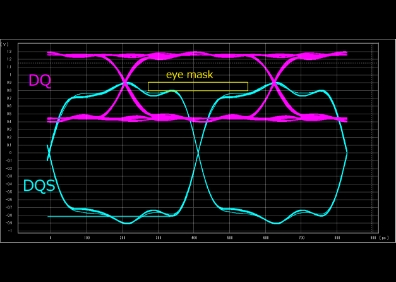

SI simulation for DDR SDRAM

We design board which satisfied Signal Integrity(SI) about DDR SDRAM Interface.

Simulator:COLMINA CAE Signal Integrity (FUJITSU)

DDR4 SDRAM Layout

DQ and

DQS Signal's Topology

DQ and

DQS Signal's eye diagram

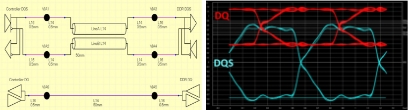

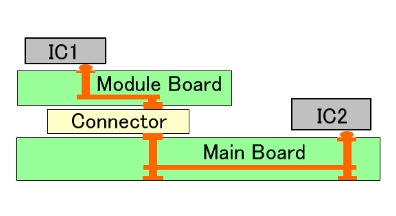

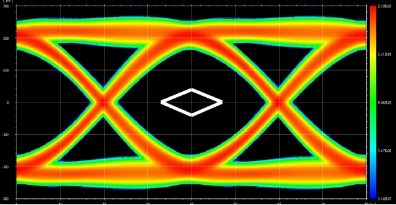

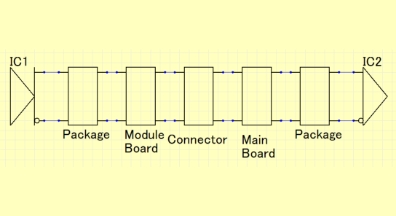

SI simulation for High speed digital channel

We design board which satisfied Signal Integrity(SI) about High speed digital channel.

Simulator:COLMINA CAE Signal Integrity (FUJITSU)

Interconnect between main

board andmodule boardt

25Gbps signal's eye diagram

Channel Model

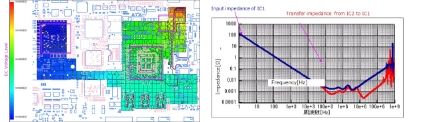

Power Integrity

DC drop simulation

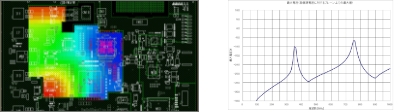

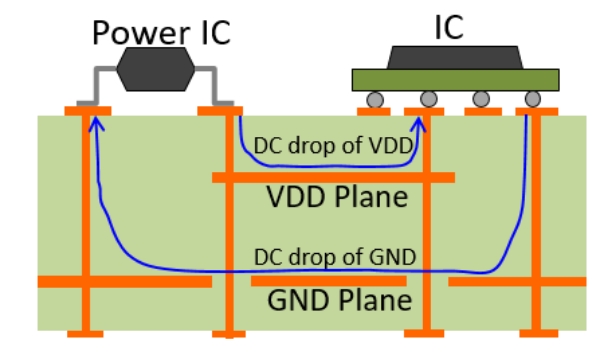

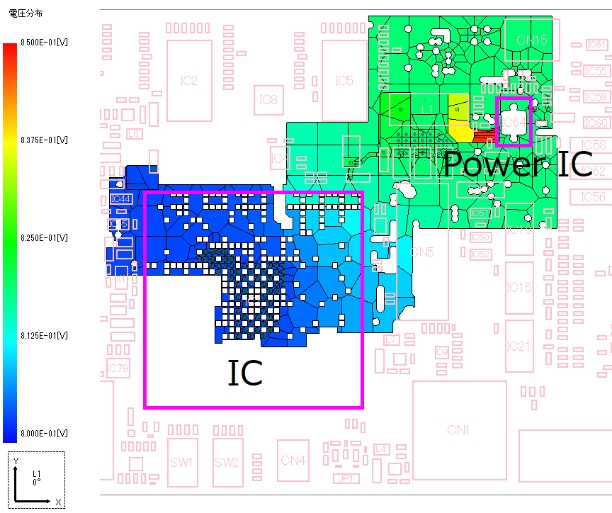

We propose optimized Power Distribution Network designs by electrically analyzing the VDD and GND net (PDN) from the power supply element (VRM) to the IC Devices.

Simulator:COLMINA CAE Power Integrity(FUJITSU)

DC drop simulation model

DC drop simulation result Voltage drop from Power IC to IC

Impedance simulation

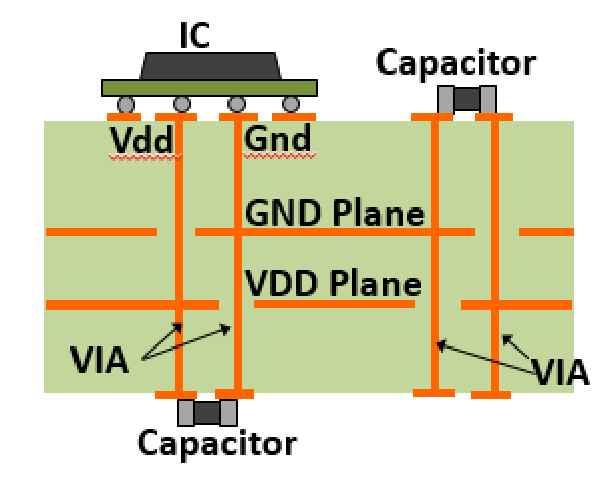

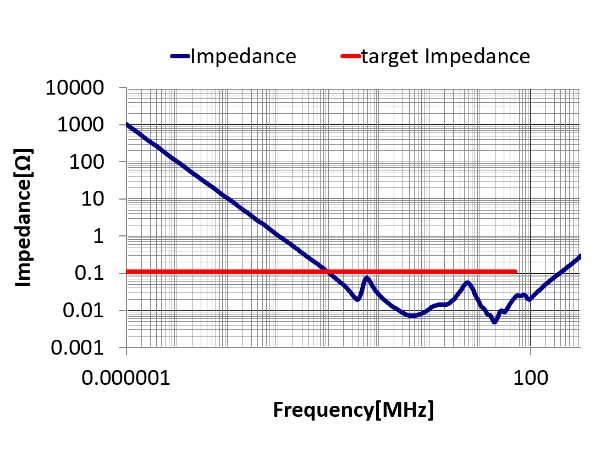

For a low power impedance, we propose the design of the power distribution network (PDN) including the VDD/GND plane, vias, and capacitor.

Simulator:COLMINA CAE Power Integrity(FUJITSU)

Impedance simulation model

Impedance simulation result

Impedance of PDN observed from IC

Physical Simulation

Physical Simulation

We support the optimization packaging design for the customer by our Thermal Management Analysis and Packaging Stress Analysis.。

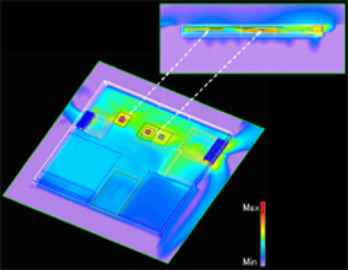

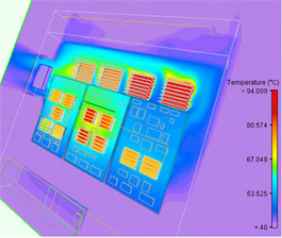

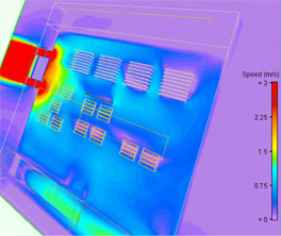

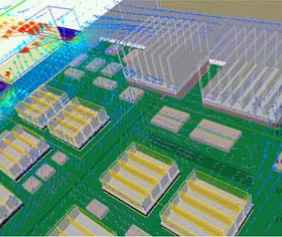

Thermal Management Analysis

We perform verification and evaluation for thermal structure, responding to each customer's

thermal problems for electronic devices.

By performing our thermal management analysis in the early stages of the development phase, we help our

customers in reducing cost and time during the development process.

- Highly precise modeling

- Optimization of radiating fin shape

- Optimization of flow path structure and/or inlet/outlet port

- Numerical evaluation for unmeasurable fine structure

- Smooth modeling in collaboration with a variety of 3D tools(STEP, SAT, STL, iges, Pro/E etc.)

- Calculation of junction temperature by estimating temperature rise of electronic device

- Evaluation of cooling structure inside casing of electronic device

- Verifications of results represented by arbitrary cross-section distribution map and/or vector is available by visualizing flows for temperature/speed/fluid

Temperature distribution of laptop PC

Analysis Tool:FLOTHERM

Temperature distribution representation

Air speed distribution representation

Flow representation

Flow representation (Enlarged view)

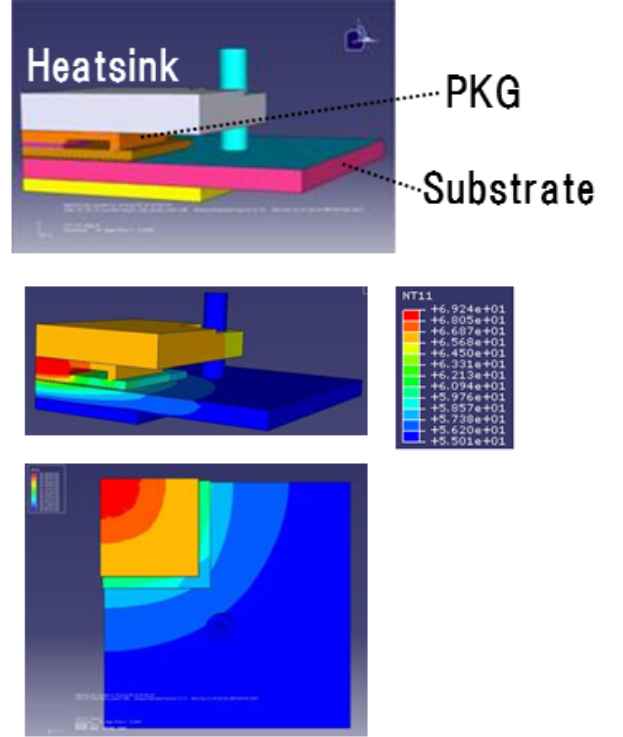

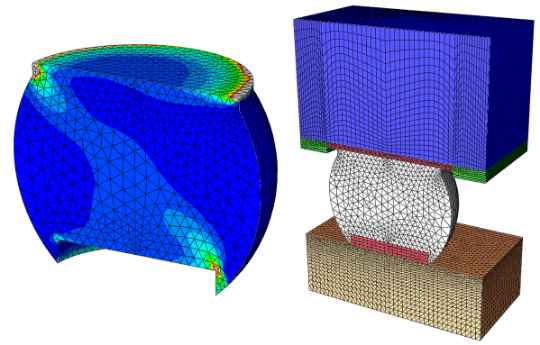

Packaging Stress Analysis

The heat generated at the time of component packaging causes substrate warpage and gives

stress on the component joints, decreasing packaging yield and product reliability. Analyzing such

problems in packaging in a way consistent with customer's point of view, we propose optimal packaging

design by suggesting packaging location and stress improvement countermeasure best suited to each

customer.

Performing simulations in the early stages of the development phase will greatly reduce the number of

verifications for prototypes, resulting in the reduction of cost and time during the development process.

- Fully utilize the extensive experience and performance of our company and Fujitsu Group combine

- Provide non-linear analysis and coupled analysis that take into account the temperature dependency of various material physical property value

- Accommodate highly precise analysis, providing large-scale analysis by mesh refinement

- Perform qualitative and quantitative verifications based on visualization and quantification of stress/strain distributions

- Perform highly precise life prediction by matching simulation and actual devices

- Perform modeling in collaboration with a variety of 3D tools(Pro/E, VPS, step, iges, inp, etc.)

Type of Analysis

- Stress and thermal stress analysis

- Warpage behavior simulation

- SMT board level reliability analysis

- Dynamic shock analysis

- Structural strength analysis

- Vibration analysis

- Modeling service for simulation

Analysis Tool:・ABAQUS(/Standard,/Explicit)

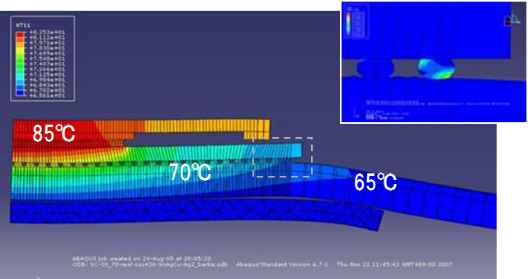

【1】Case Example : Stress Analysis by Heat/Structure Interaction

Evaluate lifetime by calculating lifetime test acceleration factor based on plastic strain analysis of solder bump.

note) ABAQUS : registered trademark of Dassault Systèmes.

Temperature distribution analysis

Thermal cycle test

Power cycle (Actual Performance)

Zooming analysis

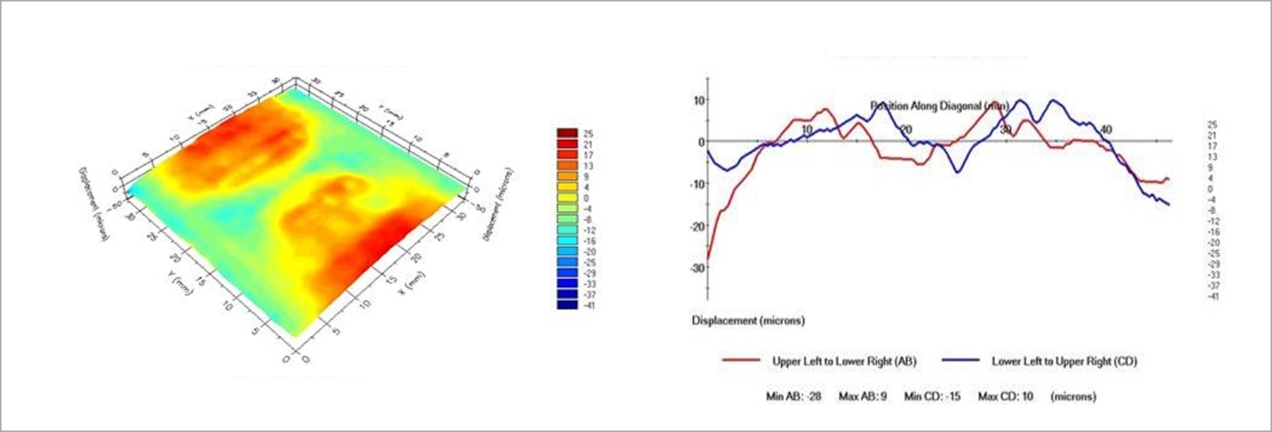

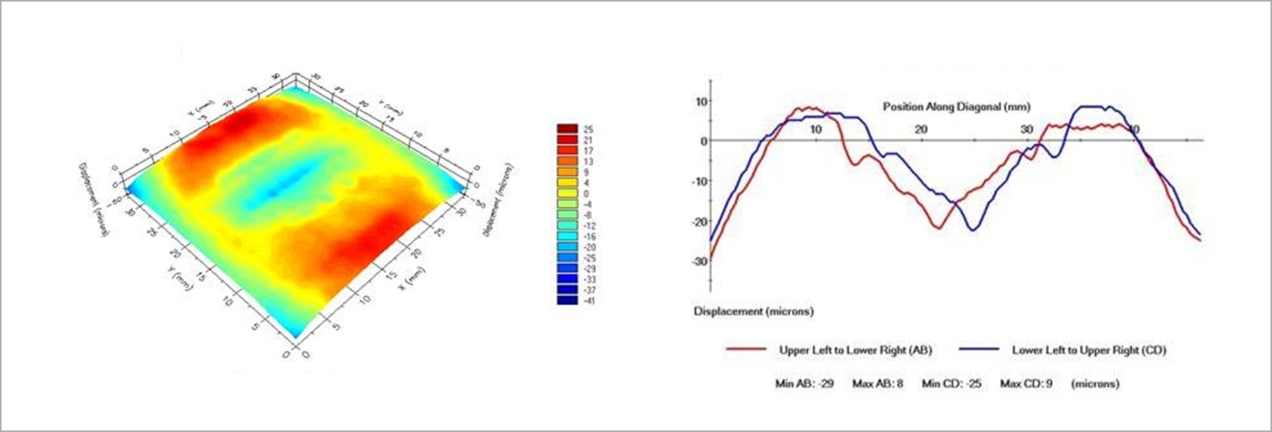

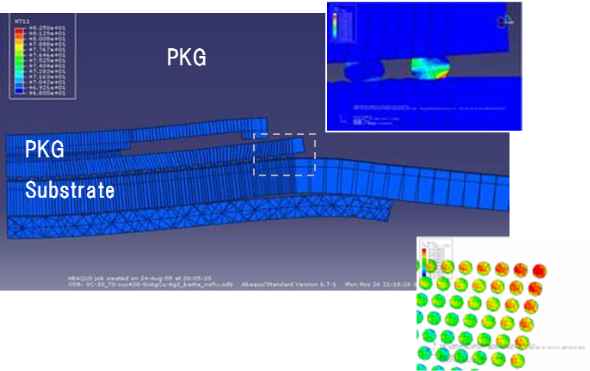

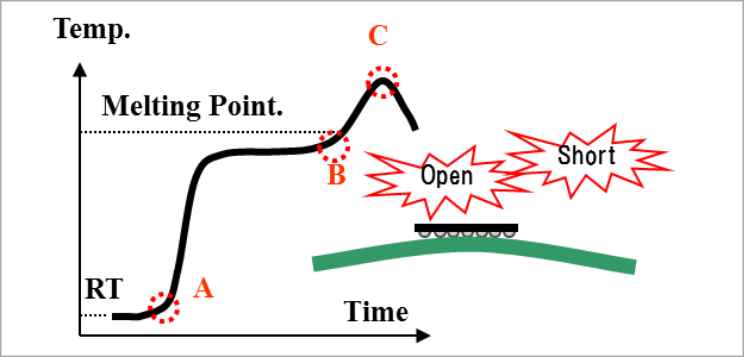

【2】Case Example: Warpage Behavior Analysis of PWBs

Propose optimal pattern design to reduce connection failure resulting from warpage by analyzing substrate warpage behavior caused by the heat at the time of component mounting.

Warpage behavior analysis

Example of BGA disconnection

At room temperature (A)

At reflow temperature (B-C)

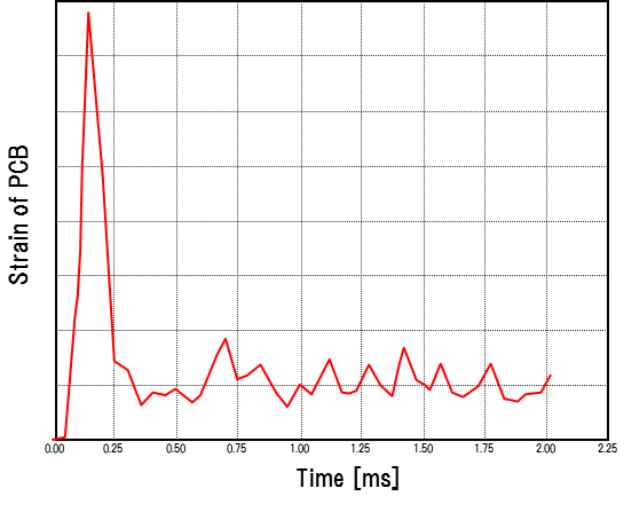

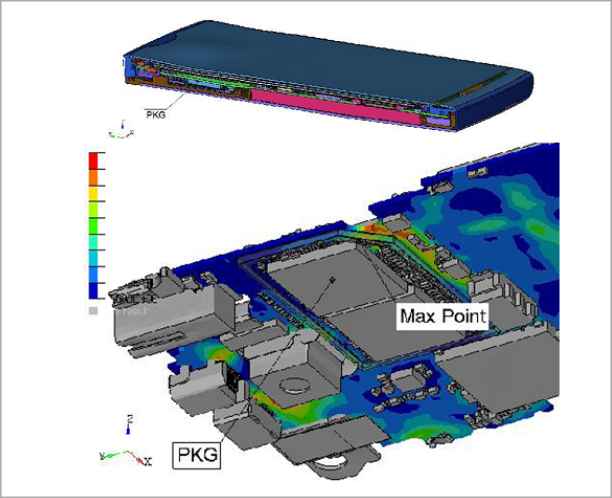

【3】Case Example: Dropping Impact Analysis

Distortion distribution of assembled printed circuit board under dropping impact

will be analyzed.

Proof stress through dropping impact will be evaluated from these impact strain

simulation.

Distortion distribution of assembled printed circuit board, especially, precise analysis of neighborhood of IC package

Strain behavior of dropping impact with millisecond time at neighborhood of IC package