Solution Services

Reliability Evaluation,

Failure Analysis

Reliability test and failure analysis

Reliability test and failure analysis

In response to customer requests, we conduct a wide variety of reliability tests and conduct failure analysis suitable for elucidating failure mechanisms.

Reliability Evaluation

Reliability Evaluation

We provide a wide range of reliability evaluations tailored to varied customer needs and requests.

- Provide reliability evaluations that comply with relevant standards (JEDEC, MIL, IPC, etc.) for connectivity, insulation, and heat resistance, etc.

- In addition to reliability evaluation, perform a series of evaluations/analysis from environment/life test to failure analysis.

- Design and manufacture a test PCB for reliability evaluation depending on the customer's needs.

Representative evaluation equipment

- Temperature Cycling

- OIL-DIP

- Tensile Tester

- Temperature Humidity Bias Life Test

- Highly Accelerated Temperature and Humidity Stress Test

Temperature Cycling

Temperature Humidity Bias Life Test

Failure Analysis

Failure Analysis

We perform a failure analysis best suited for the clarification of the failure mechanism.

- Investigate up as far as the mechanism by analyzing the defective products to suit each customer's purpose.

- Accept just visual inspection of connection in PCB/parts or other internal structure or residual analysis alone.

Analysis procedure and sample results

Propose an optimal method of analysis to suit each customer's purpose of analysis. Beginning with non-destructive analysis, we prevent an oversight of symptom by performing destructive analysis.

Non-destructive analysis

STEP1:Visual Observation

STEP2:X-ray observation

STEP3:Net Analysis

Destructive analysis example

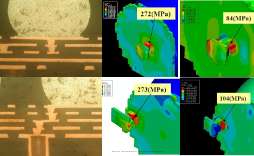

■ Case of Evaluation

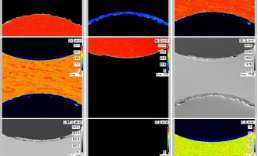

Plane and cross section polishing observation

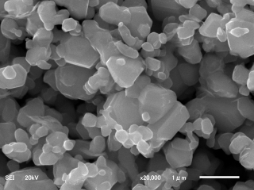

SEM observation

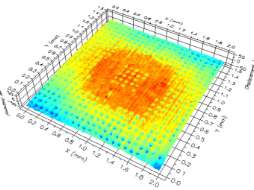

Shadow moire observation

■ Case of Analysis

EPMA Map

Structural Analysis

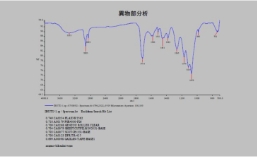

FT-IR Analysis

Representative analysis equipment

- EPMA (Electron Probe Micro-Analysis)

- Energy dispersive X-ray spectroscopy (SEM-EDS)

- FT-IR (Fourier Transform Infrared Spectrophotometer)

- X-ray Fluorescence Spectrometer

- X-ray inspection equipment(CT)

EPMA

SEM-EDS

X-ray inspection equipment(CT)